Rethinking Seed Coating in a Regulatory-Driven World

Microplastics have become a top environmental concern—and seed coatings are now in the spotlight.

Each year, thousands of tons of microplastics enter agricultural soils, where they accumulate and persist. In response, the European Commission has enacted a restriction on intentionally added microplastics under the REACH regulation.

By 2028, all seed treatment products placed on the EU market must be microplastic-free.

The message is clear: the time to reformulate is now.

Learn more about EU microplastic regulations at the European Chemicals Agency (ECHA).

Replacing Film Formers Without Sacrificing Performance

Acrylic-based binders have long served as the film-forming backbone of seed coatings. They deliver adhesion, dust control, flowability, and pigment stability.

However, their classification as non-biodegradable microplastics means they must now be replaced.

The challenge? Develop a binder that retains—or improves—functionality while meeting stringent environmental standards.

The Tensiofix® Microplastic-Free Binder

Ajinomoto Agro Solutions has developed a biodegradable binder that goes beyond a single substitution.

Built on decades of formulation expertise, this solution provides a clean-label alternative to acrylics, enabling microplastic-free seed coatings without compromising on performance.

The binder serves as the central film-forming agent, with validated performance across key coating functionalities including adhesion, wetting, dispersing, thickening, and pigment control.

Proven Technical Validations Across Key Parameters

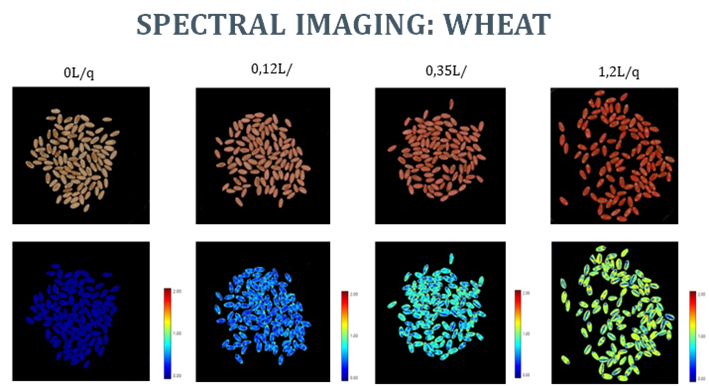

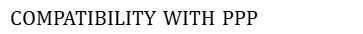

Validated using Heubach testing, spectral imaging, flowability indexes, and phytotron germination analysis. Tested across crops (barley, wheat, sunflower, corn) and with various active compounds.

Figure 1. Spectral imaging analysis – Wheat

Performance That Stands Up to the Benchmark

- Less dust: Heubach values well below ESTA thresholds

- Even pigment distribution (validated via spectral imaging)

- Maintained seed germination (non-phytotoxic)

- Full compatibility with common PPP.

Figure 2. Heubach dust value comparison at multiple doses

Real-World Formulations Validated Across Actives

Beyond benchmark testing, the Tensiofix® microplastic-free binder has already been integrated into real formulation examples using different active compounds:

- Fludioxonil (25 g/L FS)

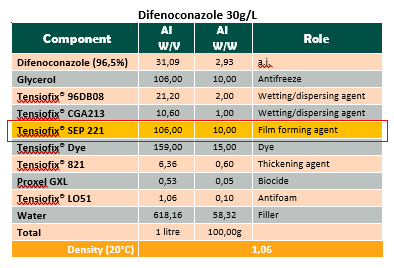

- Difenoconazole (30 g/L) (see Table 1)

Each of these passed long-term storage tests at RT, 54°C and -10/+50°C, with full performance stability. The binder replaced acrylics while maintaining adhesion, flowability, and compatibility—confirming its readiness for commercial use.

Table 1. Difenoconazole 30g/L – Tensiofix® microplastic-free binder formulation

Designed for Simplicity, Safety, and Sustainability

Formulator-friendly:

- Easy to use

- Biocide-free

- REACH-compliant

- Fully supported

- EPA 40CFR

Benefits:

- Cleaner labeling

- Secure supply chain

- Regulatory readiness

- No need to reformulate again in 2 years

- Applicable and align with bio solution concept

- Cost Effective

Let’s Reformulate the Future – Together

This isn’t just a new product.

It’s a new standard.

The Tensiofix® microplastic-free binder is ready—tested, validated, and scalable.

For more information:

For technical inquiries: tensiofix.tech.service@aoc.ajinomoto.com

For sales inquiries: tensiofix.sales@aoc.ajinomoto.com

Or simply scan the QR code below to connect directly with our formulation experts.

Scan the QR code

Let’s create solutions that leave no trace—except your mark on the future.

Ajinomoto Agro Solutions – Some call it magic,

we call it science…Driven by Responsibility.